SolidWorks [Advanced Mechanical Design, Modeling & Simulations]

About Course

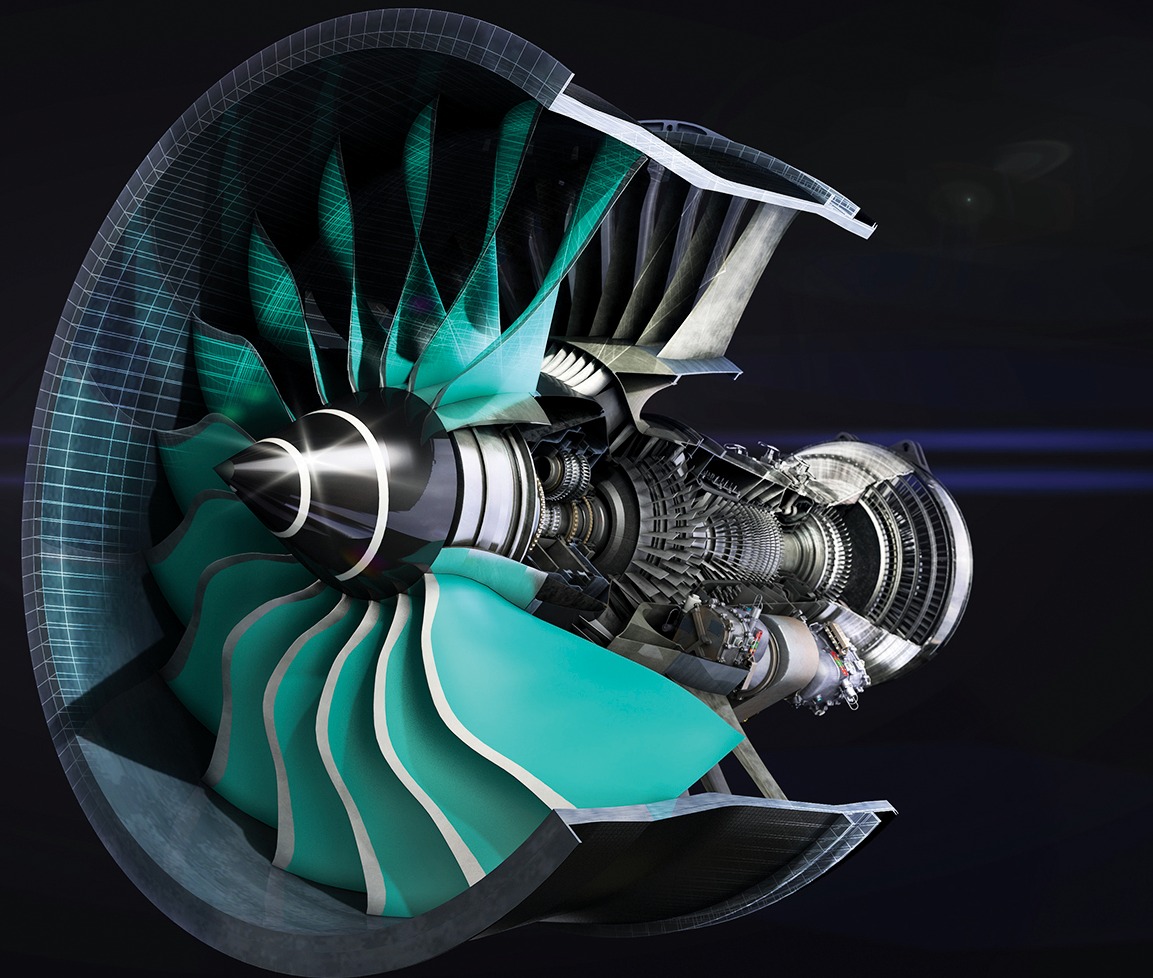

“Simulate your mechanical designs & generate your models”

SolidWorks enables you to create parametric models of parts and assemblies and make detailed drawings of those parts and assemblies more professional.

It offers numerous benefits for product design and development, including increased productivity, enhanced collaboration, and cost reduction. Its user-friendly interface, robust features, and simulation capabilities make it a powerful tool for bringing ideas to life from concept to manufacturing.

It is one of the most popular products in the 3D mechanical CAD market and caters for the mechanical engineer’s design needs.

Course Highlights.

With our extensive training on SolidWorks, you will learn how to:

- Create drawings of your designs

- Create parts and build assemblies

- Create parametric sketches of your models

- Learn how to generate Isometric and perspective views with 3D shapes

- Create and control different versions of your parts with configurations

- Automate design modification with equations and excel design tables

- Develop concurrent engineering-based user environment for model development, analysis, design, visualization, and verification.

Course Benefits

- Increased Productivity and Efficiency:

- Enhanced Collaboration

- Cost Reduction and Time Savings:

- Advanced Simulation and Testing:

- Customization and Innovation:

- Industry Applications:

Prerequisite

No previous experience with SolidWorks is necessary, but a general knowledge of AutoCAD or other CAD tools, Mechanical background and Mechanical terms is an advantage.